|

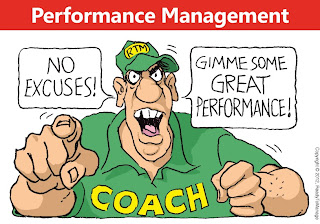

| Between a Rock and a Hard Place ? |

The conflicting drivers are naturally the inputs.

A) What is being done

B) What it is costing

Note "what is being done" is really producing output eg "widgets manufactured" or"meals served" but this is an input to the energy management perspective - Our energy manager reads it from a screen.

The objective is easily stated - "deliver comfort at least cost".

("Production" or "services" may substitute for "comfort", but "least cost" is usually set in stone :)

This implies the comparison of one input with the other where the ratio is performance -

"what you get for what you spend"

Unfortunately both of these inputs are usually represented by two horribly fallible systems.

What is being done ?

is represented by a Building Management System (BMS) or Building Control System (BCS). This may be a a brand new elegant well-designed system with just the right level of GUI and dashboard - or it may be the one you have !

Yes all of the fortunate energy managers in the world have inadequate, old, poorly maintained, not-fit-for-purpose control systems. Less fortunate energy managers have either new inadequate, poorly-commissioned, not-fit-for-purpose control systems. The least fortunate energy managers manage more than one building and face a set of control systems whose wiring looks like an explosion in a spaghetti factory.

|

| Yes this IS your basement |

Note to non-energy managers - many BMS systems may control thousands or tens of thousands of conditions, temperatures valves etc - it can be hard to see the wood from the trees even if you do have perfect documentation (which you dont !)

What it is costing ?

is related in some way to the utility bills that are paid. Often a billing verification system may be in place (because this is the only service function in the world that charges for a commodity to be delivered) but does so in such an unreliable way that it pays you to systematically check the bill before you pay it!

|

| Running up a Tab |

Naturally, the utility bills do not typically accurately reflect the energy used, because that would assume reliable metering, reliable meter reading and given automated meter reading, reliable data processing of the steps between.

However these two systems are what the typical energy manager sees. A dashboard showing energy historically used (allegedly) and a control system showing (+/- sensor and actuator failure) what is happening now.

It is no surprise that comparing the two is largely futile.

One represents long term history with no activity context

The other represents current status with no cost context

And the energy manager has the job of comparing the two to get a notion of performance. So often they fall back on "soft-energy management" - behavioural change that is useful but only part of the problem

|

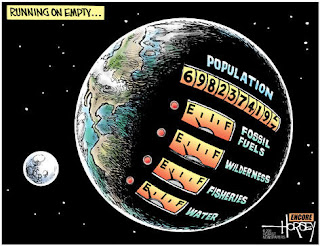

| Behavioural Change Coach |

Many energy managers have tens, hundreds or thousands of such buildings "on their watch" so cannot ever be as thorough as they would like. The tasks involve time, spreadsheets, time, assumptions, time and an ability to work with an inadequate budget, oh and more time to justify achievements (or lack of them).

When between a rock and a hard place there is a classic play. You wedge the two impassable objects, into place and build a bridge across the top ( I wish I could sketch).

|

| Bridging the Gap |

Here are some possible thoughts

Suppose you knew the patterns of typical activity, the size of plant, what it is for (heating chilling etc) and when. Suppose you had a really smart tool that could see patterns in data so instead of interpreting a thousands graphs it would draw conclusions from the numbers underlying the graphs and prioritise activity, while also flagging inputs it did not believe.

Suppose this system could assimilate much of the knowledge of your energy manager and your operations could emulate much of the thinking and processing required to reach decisions and justify those decisions (yes and even print them out in nice to read reports).

This is the sort of assistant a company might provide its energy manager with and would find it would pay back in happier staff, better productivity lower costs and the warm fuzzy feeling of "doing the right thing".

Bottom line - if you got this far is - any company can perform far better if the energy management function is supported with the right tools.

If you do agree then please "comment", "like", "forward", or "tweet" because most enterprises simply don't understand the problems you face !

Thanks - James

By the way do Feel free to give us a shout if you think we can help!