I was editing a video of our new energy analysis tool last Sunday, when the son of my neighbour (an engineering student) asked me, "Does it make any sense that if you lower your thermostat at home by one degree that whoever you are you will save 5% of your heating energy"?

Now he is a smart young man - so we started discussing it...

We first compared their house with mine – mine is bigger but older (1684 – the oldest chalet in the village and the wiring standards are pre-Faraday also ! ), both are wood frame – his far better insulated but his parents prefer much higher indoor temperatures.

Their heating system is modern, though both of us heat with local wood, I use a traditional wood-fired oven. His parents use more consumer electronics. So, pretty much the only things these buildings have in common is the local weather (Swiss Alps), the Laws of Physics – and the fascination the owners have in sustainable living !

If we were to rely on the disinformation and nonsense on the subject published by authorities and people who should know better, we would very rapidly have reached the wrong answer.

I searched “turn thermostat degree save” at "scroogle" http://www.scroogle.org (scroogle allows me to use the familiar Google tool but eliminates bias in results due to their recording my location and normal search interests etc).

The results (tabulated below) suggest that most “authorities” put savings at 1% - 6% per continual degree (Fahrenheit) of heating turn-down, with the average at around 3%. So thats a specific impact. If my mortgage broker said I could save 3% on repayments I would be excited – but if the quotation was 3% plus or minus 3% I would be far less, motivated. When the savings are quoted as 1% savings per eight degree-hours as six out of twenty opinions suggested, as a consumer I would be completely confused. There is archaic Anglo-Saxon phrase for communication standards of this ilk, to wit : “complete http://en.wikipedia.org/wiki/Bollocks”.

Some authorities advise that climate, construction and preferences have an impact, but this is not reflected in their “facts”. For example there is no obvious geographic or weather pattern (extremes were reported in Great Britain, California & New Mexico and more modest figures in Wisconsin, Washington DC, Louisiana and Kentucky).

So lets have a think about this...

Surely we must think in terms of a particular local climate. Now we have local weather data for anywhere on the planet – so getting a local set of degree-day data is easy.

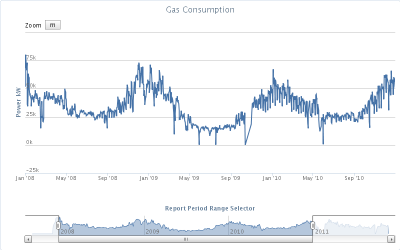

First you need to select a balance temperature - the temperature when no heating is required . To do this you can just map consumption against weather. And to do that we need to upload consumption data. Maybe we have it written down or in a spreadsheet, or better yet we can download it from a Smart-Metering provider or maybe a utility company. So we can upload it somehow … If we are lucky we have a good three years of data – but anything is better than nothing ! (OK I am cheating this is gas data from a client - I count cords of wood burnt )

Given weather and consumption we could find the balance temperature of the two buildings. Here is theirs:

Thats fairly clear isn't it! Above 11.5 Celsius – no heat is required – in summer use is for hot-water cooking etc. So balance temperature is 11.5 Celsius. A useful figure to know if you are controlling a building...

(By the way four years ago it was proven conclusively by an “authority” that it was impossible to automatically calculate balance temperatures – “Whooops!”)

So now we can draw a Degree-Day diagram - lets assume fuel has been logged in “logs”. (Logging is actually throwing a log on a rope over the front of a boat and writing down how long it takes to sail past – logging boat lengths for navigation – Think Columbus)

So on a very cold day we burn 14 logs – but in summer only 2. Each day represents a weather load and a number of logs. For fun we also coloured the over-normal spends red (because we can) - this represents an "inconsistency cost"

In an office the scatter is important by day of week because occupancy patterns change (or should)

Mission nearly accomplished ...

So to calculate how much we save by dropping the internal temperature by one degree, all we need to do is move each dot down and to the left by one degree-day representing a reduction in load (parallel to the best-fit line, but not allowing the consumption to intersect the bottom or left axis - negative consumption disallowed).

For this building one degree is worth about 10% - Celsius so some of them are right !!!

Hmmm – a new feature for version two (planned January 2012 release) – So we can calculate how much you would save in your house or other building, based on your weather, your energy use patterns and on your building – then you could rely on facts rather than letting some “authority” on energy have a guess !

If you like the idea, do watch the screencast at http://kWIQly.com for a bit more information – its illustrative and three minutes only so is by no means complete.

And, even if you think what we are saying and doing sucks – please do tell us – we need your feedback

Finally if you are an authority on energy, a utility company, or a smart meter operater, or even if you have your own reliable energy records, do get in touch.

Maybe we can figure out something – Just like my young neighbour Ueli and I did on Sunday afternoon. And if we can figure stuff out for people, something that they can use to really save energy based on their buildings, based on data from their buildings – rather than some irrelevant benchmark – wouldn't that be cool – or maybe hot - to a degree !

Oh - and here are those authorities on the subject I promised

Ref (links below)

|

Statement

|

% Saved for

1 Fahrenheit change

|

Location

|

1

|

Each 1-degree drop for an eight-hour period reduces your fuel bill about one percent.

|

3%

|

US

|

2

|

For each 1 degree you turn down the thermostat in the winter, you’ll save up to 5% on your heating costs.

|

5%

|

California

|

3

|

Save: 1 - 3 percent per degree, for each degree the thermostat is set above 72 degrees

|

1%-3%

|

California

|

4

|

For every degree you lower your heat in the 60-degree to 70-degree range, you'll save up to 5 percent on heating costs.

|

5%

|

California

|

5

|

The rule of thumb is that you can save about 3% on your heating bill for every degree that you set back your thermostat” full time, says Bill Prindle, deputy director for the nonprofit American Council for an Energy-Efficient Economy.

|

3%

|

US

|

6

|

One rule of thumb is that each degree Fahrenheit you set the thermostat back over an eight-hour period translates to a 1 percent savings in heating costs.

|

3%

|

|

7

|

No value given

|

|

UK

|

8

|

In fact, you will save an average of 3% on your monthly bill for every degree you turn your thermostat down

|

3%

|

Kentucky, Louisiana

|

9

|

In general, adjusting the thermostat by just a single degree in the summer can either cut or increase cooling energy use by about 4-8%.

|

4%-8%

|

MA

|

10

|

Typical savings are about one-percent per degree set-back for each eight-hour period.

|

3%

|

|

11

|

Yet, for every degree you lower the thermostat, you'll save between 1% and 3% of your heating bill.

|

1% - 3%

|

|

12

|

For every degree you raise your thermostat above 80 you will save approximately 2 - 3 percent on the cooling portion of your bill.

|

|

|

13

|

In heating mode, reducing your thermostat setting

by 1 degree Fahrenheit for eight hours will save about

1 percent on your heating bill. In cooling mode, e ach

degree you set your thermostat above 75 degrees

Fahrenheit cuts your cooling costs by about 3 percent.

|

3%

|

WI

|

14

|

HVAC experts estimate that for every degree the thermostat is dialed down, you can save 1-3 percent on your heating or cooling utility bill.

|

1-3%

|

US

|

15

|

You can save 3 percent on your heating costs for every degree you reduce the temperature below 70 degrees F. for the entire heating season.

|

3%

|

Washington, D.C.,

|

16

|

By turning your thermostat back 10°–15° for 8 hours, you can save about 5%–15% a year on your heating bill—a savings of as much as 1% for each degree if the setback period is eight hours long. The percentage of savings from setback is greater for buildings in milder climates than for those in more severe climates.

|

1-3%

|

|

17

|

A savings of 3% to 5% can be realized each month for every degree the room thermostat is lowered.

|

3% - 5%

|

New Mexico

|

18

|

For every degree you turn it down, you can save about 10% of your heating bill (Celsius)

|

6%

|

UK (BBC)

|

19

|

Your heating costs will go up by 8% each time you increase the temperature by just one degree. (Celsius)

|

5%

|

Carbon Trust

|

20

|

No value given

|

|

|

Twenty results

"21 Aug 1999 ... Gradually, you might be able to go down 3 or even 4 degrees comfortably and save a chunk of money. 4. Try turning down the thermostat 5 to ..."www.care2.com/greenliving/10-thermostat-tips-save-money.html

"Reduce the setting to 55 degrees at the end of the day. (For each 1 degree you turn down the thermostat in the winter, you'll save up to 5% on your heating costs ..."earth911.com/location/california/flex-your-power/

"(Save: 1 - 3 percent per degree, for each degree the thermostat is set above 72 ... your dishwasher only when it is fully loaded, and turn off the dry cycle and air ..."www.consumerenergycenter.org/tips/summer.html

"Turn down your thermostat to 68 degrees. For every degree you lower your heat in the 60-degree to 70-degree range, you'll save up to 5 percent on heating ..."www.consumerenergycenter.org/tips/winter.html

"2 Nov 2008 ... We already keep the thermostat at 63 degrees…no exceptions. And socks, sweaters and blankets are ready to go. I will not be turning the heat ..."www.iwillteachyoutoberich.com/blog/tip-2-turn-your-thermostat-down-3-degrees/

"3 Dec 2010 ... Does turning down the thermostat at night save energy? ... to bed, turning the thermostat down from 68 degrees Fahrenheit to 60, then turning it ..."www.straightdope.com/columns/read/2970/does-turning-down-the-thermostat-at-night-save-energy

"You can also make savings by using your controls more effectively: Turn down your room thermostat by one degree: save around £55 and 230kg carbon dioxide ..."www.energysavingtrust.org.uk/In-your-home/Heating-and-hot-water/Thermostats-and-controls

"14 Sep 2011 ... There are literally dozens of things you can do to cut back on your heating (and cooling) costs in your Jeffersonville home."www.accutempcomfort.com/blog/energy-savings/turn-that-thermostat-down-a-degree-and-save-money-some-advice-from-jeffersonville/

"If you choose to turn up your thermostat by four degrees in the summer, you'll be saving something close to 16-32% in energy costs. You'll also be avoiding the ..."practicallygreen.com/turn-thermostat-up-by-4-degrees-in-the-summer

"In time, you might be able to go down three or four degrees comfortably and save money. • Try turning down the thermostat five to ten degrees at night, and then ..."www.homehdw.com/tips/thermostats.html

"Save money on your utility bills, and reduce your carbon footprint, by turning down ... Yet, for every degree you lower the thermostat, you'll save between 1% and ..."www.thedailygreen.com/going-green/tips/energy-efficiency-sweater-tip

"Can I turn my air conditioner off when I leave or should I leave my air conditioner on during ... For every degree you raise your thermostat above 80 you will save ..."www.aps.com/main/services/residential/FAQ/ResFAQ_52.html

"Will a programmable thermostat really save ... by 1 degree Fahrenheit for eight hours will save about ... If I turn the thermostat way up, my home will warm up ..."www.focusonenergy.com/files/document_management_system/residential_programs/managingthermostatcomfortenergysavings_factsheet.pdf

"Every 10 degrees you dial down the thermostat can knock 3 to 5 percent off your ... In other words, the amount of energy saved by turning down the thermostat ..."tlc.howstuffworks.com/home/how-to-conserve-energy-at-home4.htm

"Turn them off when their job is complete. 3. Set your thermostat at 68 degrees F. during the day and 60 degrees F. at night. You can save 3 percent on your ..."www.pepco.com/home/education/conserving/save/

"9 Feb 2011 ... By turning your thermostat back 10°–15° for 8 hours, you can save ... on your heating bill—a savings of as much as 1% for each degree if the ..."www.energysavers.gov/your_home/space_heating_cooling/index.cfm/mytopic=12720

"Turning down the heating element thermostat(s) by 10 degrees can save you as much as $10 monthly. Repairing hot water leaks can save 10's of dollars ..."www.fmtn.org/city_government/electric_utility/energy_saving_tips.html

"30 Apr 2008 ... Thermostats (usually a dial on the wall) set a maximum temperature for ... For every degree you turn it down, you can save about 10% of your ..."www.bbc.co.uk/bloom/actions/heatingcontrols.shtml

"Energy saving heating tips to increase the energy efficiency of your workplace and lower your ... Don't turn up the heating unless you really need to. Unless it's just too cold for comfort, try to keep your thermostat at 19°C. Your heating costs will go up by 8% each time you increase the temperature by just one degree. ..."www.carbontrust.co.uk/cut-carbon-reduce-costs/reasons/why-save-carbon/pages/heating-reduce-costs.aspx

"Some thermostats are equipped with schedules in which you can set differing ... In the winter months, do you turn (or does your thermostat turn) your heat down to save. ... Turn your sleeping areas down to about 17-18 degrees celcius (likely ..."askville.amazon.com/turn-heat-home-saves-energy/AnswerViewer.do?requestId=6150032