It's been a while since I had a good rant...

So here we go.We've all heard of digital control (ON/OFF), but semi-digital control is simpler - (ON) !

Practitioners of semi-digital control fit that bill - simple (as in simpleton) and are the bane of many an energy manager.

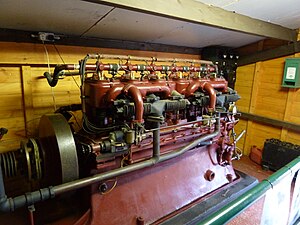

| 1925 Pelapone PD6, 17 litre 6 cylinder, petrol engine-generator set, ex a standby generator at Shrewsbury Hospital Now on display at the Internal Fire museum. (Photo credit: Wikipedia) |

Their arguments go something like this;

- Our controls company said we should keep the lead boiler enabled at all times

- Our chiller manufacturer says the chiller is designed to manage load efficiently and there is no need to switch off.

- Switching fluorescent lights off reduces their life and consumes more energy on start.

- We have to keep the service running because there is the risk of failure on startup.

Lets address these one at a time with simple cogent arguments. And a bonus at the end !

Our controls company said we should keep the lead boiler enabled at all times

Did they ? - well fire them - the controls company - not the boilers.

| Steamship "California" (Photo credit: Smithsonian Institution) |

Today a simple rule applies - if there is no demand for heat all boilers should be cold (or cooling).

The need for back-end protection of boilers is mitigated by modern materials (boiler sections that split can be protected with small shunt pumps) and economizers or condensing lead boilers overcome the problem of flue gas concentrates. Ultimately the value of energy saved requires that boilers should operate in their ideal firing temperature or not at all. If you do have problems with condensates simply fire boilers long enough to dry the flue (which requires load !).

Our chiller manufacturer says the chiller is designed to manage load efficiently and there is no need to switch off.

| Fire Engine The ultimate chiller ? :) (Photo credit: freefotouk) |

Useful reference here (not associated with kWIQly)

All plant has a startup sequence and it is for starting (because stopping is legitimate)

Switching fluorescent lights off reduces their life and consumes more energy on start.

Useful reference here (not associated with kWIQly)

The only discussion is on CFL lights but well designed lights should be switched off if even for 5 minutes. With tube fluorescents the argument is old after a few milliseconds (years ago discrete component ballasts where a different story)

The only discussion is on CFL lights but well designed lights should be switched off if even for 5 minutes. With tube fluorescents the argument is old after a few milliseconds (years ago discrete component ballasts where a different story)

We have to keep the service running because there is the risk of failure on startup

| Rescue Helicopter over Deception Bay-5= (Photo credit: Sheba_Also) |

Yup you switch them off and maintain them when not in service. Perhaps you exercise the plant for a while periodically to keep lubricants from drying etc - but you switch them off.

Finally - The Bonus...

| British SAS motto Who Dares Wins ! (Photo credit: Wikipedia) |

We have chilling demand year round in our processing centre and so we dare not switch off the cooling.

Engineers worth their salt use free resources when available (I have seen numerous buildings with comfort chillers running 24/7/365) when they are targeting a delivery temperature of 5C (41F) and air temperatures are below freezing out side - the cure - ventilation. Also bear in mind that processor load varies, heat production is falling and heat tolerance is rising - so review your specs !